(MainsGS2:Government policies and interventions for development in various sectors and issues arising out of their design and implementation.)

Context:

- Recently, Quality Control Orders (QCO) have been issued for fibers like cotton, polyester and viscose that constitute the basic raw materials for the majority of the Indian textile and clothing industry.

- While the standards were available earlier too, these are now revised and made mandatory for a few, and yet to be finalised for others.

Fibers covered:

- International manufacturers of these fibres, who supply to India, are also mandated to get a certificate from the Bureau of Indian Standards (BIS), which is the certifying authority for the QCOs.

- The Indian textile and clothing industry consumes both indigenous and imported fibres and filaments.

- The imports are for different reasons — cost competitiveness, non-availability in the domestic market, or to meet a specified demand of the overseas buyer.

- The main aim of the QCO is to control import of sub-quality and cheaper items and to ensure that customers get quality products.

- The entire supply chain, from the textile manufacturers to exporters, has so far focused on quality standards prescribed by the buyers.

Challenges due to new mandate:

- India imports annually 50,000 - 60,000 tonnes of viscose fibre and its variants such as Modal and Tencel LF from nearly 20 countries.

- In the case of polyester, almost 90,000 tonnes of polyester fibre and 1.25 lakh tonnes of POY (Polyester Partially Oriented Yarn) are imported annually.

- The overseas fibre manufacturers sell not only to India but to other countries too.

- The supply of some fibres to India is in small quantities thus getting the certificate from the BIS involves a cost and hence not all are interested in getting the certificate.

- The Indian textile manufacturers who are dependent on these suppliers for the raw material will have to either look at other suppliers or lose orders.

- The textile buyers, be it domestic or international, have established a supply chain over the years and when there are constraints because of certification, the value chain is disrupted.

Way forward:

- Be it viscose or polyester, some varieties of the fiber have special functional properties and separate HS (Harmonised Commodity Description and Coding System) code when imported but these are bundled in the QCO and thus have uniform quality standards.

- The textile industry imports just small quantities of such fibres and restricting its availability will deny Indian consumers of niche products.

- The textile industry is of the view that import of specialty fibres that are used as blends with other fibres should be made available without restriction.

- Also, any overseas applicant for the BIS certificate should get it without delay after inspection.

- Several textile units use lower grade fibres that are generated from rejects and wastes and these are not covered under the QCO.

- Further, polyester spun yarn mills in the MSME sector need capital support to set up labs to test products.

- The QCO should be implemented only after the ambiguities are cleared and the anomalies set right, says the industry.

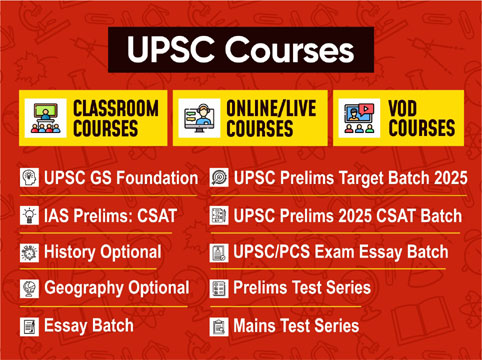

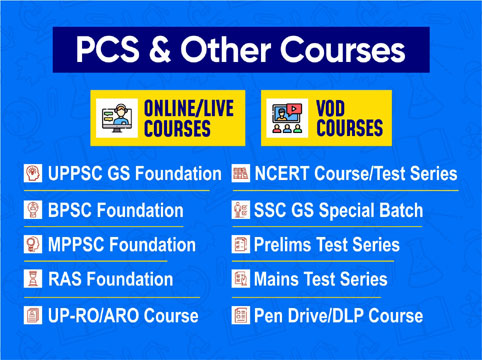

Contact Us

Contact Us  New Batch : 9555124124/ 7428085757

New Batch : 9555124124/ 7428085757  Tech Support : 9555124124/ 7428085757

Tech Support : 9555124124/ 7428085757